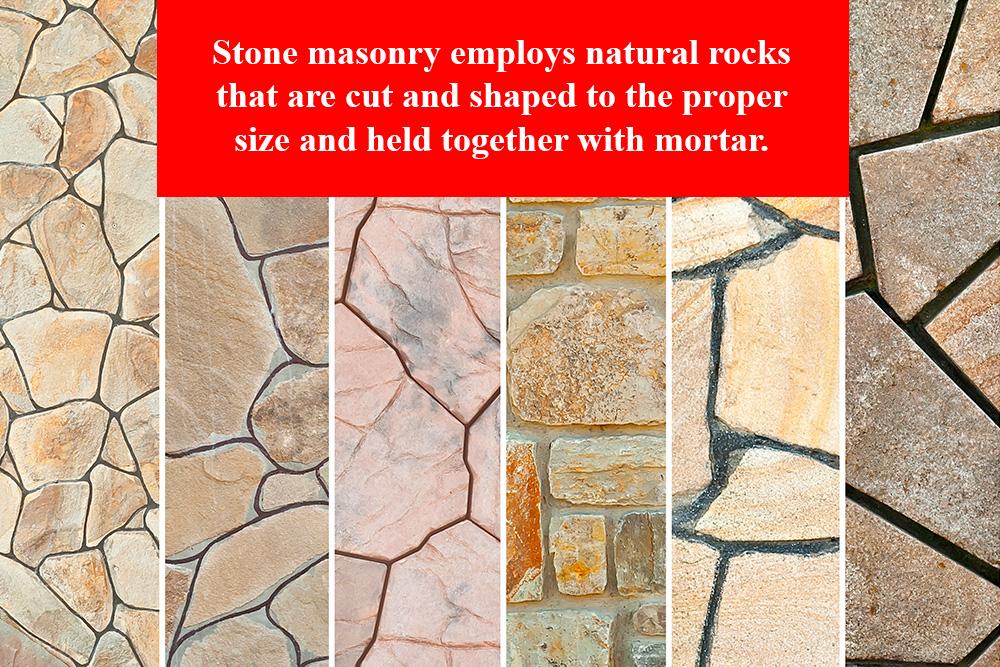

Stone masonry employs natural rocks that are cut and shaped to the proper size and held together with mortar. Stone is a popular choice for masonry projects as it creates an elegant look, is weather-resistant, requires relatively little maintenance, and is suitable for use in foundations, floors, stairs, walls, and fireplaces. There are five main types of natural stone used in commercial masonry & stone masonry restoration:

1) Limestone is a classic choice for outdoor masonry and comes in white, tan, and gray shades. Limestone is an excellent choice for decorative stone masonry and can be cut into irregular and natural-looking shapes.

2) Sandstone has been a popular choice for centuries. It is well known for its natural feel and comes in shades of white and tan.

3) Granite is one of the most durable stones and can last for centuries. Granite colors range from white to pink and will weather into a look of classical architecture as it ages.

4) Marble, like granite, marble is extremely durable and can last for a long time. Marble is most commonly used in commercial buildings for steps, pillars, and foundations.

5) Fieldstone is a naturally occurring stone that got its name from being found in homesteaders’ fields who most commonly used the rocks to build foundations and fireplaces. Fieldstone is also now coming to be referred to as “found stone” as people pick up stones they have found in their travels to incorporate into construction projects as a sort of keepsake to remember a favorite place or memorable trip.

Stone Masonry Restoration Techniques

In addition to the type of stone used in masonry construction, there are a variety of masonry techniques. There are two basic categories of stone masonry, known as rubble and ashlar, with each category having sub-classifications and are broken down as follows:

Rubble Stone Masonry

Rubble masonry employs irregularly shaped and sized stones under 250 millimeters. The stones are brought directly from a quarry and are broken down to the required size with a hammer. The strength of rubble masonry depends on several factors, including the physical characteristics of the stone, the quality and proper use of mortar, the placement of through stones, and environmental conditions.

1) Coursed rubble masonry is built in layers, with the stones being five to 20 centimeters in size. While it is most often found in residential buildings, coursed rubble masonry is sometimes used for commercial masonry work. There are three subtypes of coursed rubble masonry:

- First class coursed rubble masonry has stones that are all the same height, each course of stones is the same height, and the thickness of the mortar joints never exceeds 10 millimeters.

- Second class coursed rubble masonry uses stones of different heights, courses are of varying height, and each row is only two stones high.

- Third class coursed rubble masonry uses stones of various heights with a minimum height of five centimeters. Not all layers are the same height, the thickness of the mortar joints is no more than 16 millimeters, and only three stones are used for each course height.

2) Uncoursed rubble masonry uses stones that have the corners removed with a hammer. As the name implies, uncoursed rubble masonry does not occur in layers. The cavities between the larger stones are filled with smaller stones, and the height of masonry equalizes every 40 to 50 centimeters. This type of masonry is typically inexpensive and is common in warehouses and garages.

3) Random rubble masonry arranges irregular-sized and shaped stones to create an aesthetically pleasing structure and is commonly used for warehouses and retaining walls. Stones are broken with a hammer, and the thickness of mortar joints does not exceed 12 millimeters.

4) Dry rubble masonry is similar to third-class coursed masonry. However, the stones are laid without using mortar except at the ends of the rows to prevent the stones from shifting. Because there is no mortar used, skill is required to lay dry rubble masonry.

5) Polygonal rubble masonry uses stones that have been dressed with a hammer. Because the surface stones are shaped into irregular polygons, the surface joints appear to move irregularly in all directions. Polygonal rubble masonry requires a highly skilled mason.

6) Flint rubble masonry stones are durable but easy to break down to the proper size and shape between 80- to 150-millimeters thick and 50- to 300-millimeters long. The stones on the surface are placed in either a layered or non-layered pattern and arranged in a lacing course approximately six-feet off the floor to increase the strength of the structure.

Ashlar Stone Masonry

The stones used in ashlar masonry are different than the rough-cut stones used in rubble masonry as all of the stones are worked to the same size, shape, and surface texture. Ashlar masonry uses rectangular or square stones typically laid in horizontal courses. Ashlar stones have smoother faces that fit together more tightly than rubble stones, so this technique requires less mortar. Stones have a height of 25 to 30 centimeters, with the length of each stone not exceeding three times its height.

1) Ashlar fine tooled masonry uses stones that are worked with a chisel on both sides and at both ends to remove all the unevenness across the faces, sides, and bed of the stones, so each block has perfectly horizontal and vertical edges. The height of each course does not exceed 30 centimeters, with all courses being the same height and thickness and the joints not exceeding three millimeters. Because of the amount of work needed to refine the stone, ashlar masonry is one of the more expensive masonry methods.

2) Ashlar rough tooled masonry has stones where the sides are chisel-dressed, and the surface is roughed up with a tool. Also called bastard ashlar, a 25 millimeter-wide strip is cut on all four sides of the stone, and the thickness of the mortar joints is no more than six millimeters thick.

3) Ashlar quarry-faced stones are irregularly shaped and have a 25 millimeter-wide strip, cut with a chisel, along all four sides on the surface of the stone. The strip remains visible on the outside face of the stone. However, the middle of the stone surface is left as it was when it was extracted from the quarry, with the exception of any projections over 80 millimeters being removed with a hammer.

4) Ashlar chamfered stones have a 25 millimeter-wide strip cut around the outer surface of the stone with a chisel. The strip is chamfered, or beveled, at a 25- to 45-degree angle and a depth of 25 millimeters. A second 12-millimeter wide strip is carved around the middle surface, but the surface itself is left as it was extracted from the quarry. Projections over 80 millimeters are removed with a hammer.

5) Ashlar block-in course uses stones that are hammer dressed on their face and laid in courses between 20- to 30-centimeters thick with the joints being no more than six millimeters thick. Ashlar block-in course masonry is usually used for commercial masonry in such applications as heavy coastal and maintenance walls, bridges, and train stations.

6) Ashlar facing masonry is a stone facade, or veneer, laid over a rubble or brick surface. It provides all of the aesthetic appeal of Ashlar masonry at a fraction of the normal cost. The height of each course should be at least 20 centimeters high and the width of each stone approximately 1 1/2 times its height. Because of its natural strength and weather resistance, stone masonry structures can last for decades, even centuries, with proper maintenance. However, commercial stone masonry requires special care. If the proper type of maintenance is not performed in the correct manner, damage can result.

At Epic Masonry Restoration, we are commercial masonry contractors with over 20 years of experience maintaining and preserving commercial masonry. We are experts at enhancing your property’s visual appeal and maintaining its longevity, so your building always makes a great first impression. If you have a building with commercial masonry in St Paul or Minneapolis, contact us today at 1-612-353-4646 for an estimate or visit us online at EpicMasonryRestoration.com.